PTA process, Plasma Transferred Arc, is a melting welding process suitable for hardfacing on mechanical workpieces subject to wear and/or corrosion with superalloy metal powders.

PTA technology is mainly used in the conditions where abrasive wear and impact pressure coexist. Cemented carbide inlaid blocks or cast tungsten carbide particles are evenly distributed in the nickel-based or cobalt-based binder phase, which greatly improves the wear resistance and corrosion resistance of the hard surface layer.

WEDO have a team specialized in PTAW process, equipped with highly automated equipments, in the aims to better meet the requirements of customers in various industries such as petrochemical industry, machinery manufacturing, transportation and energy for solving wear and corrosion resistance, high temperature resistance, high impact and high hardness.

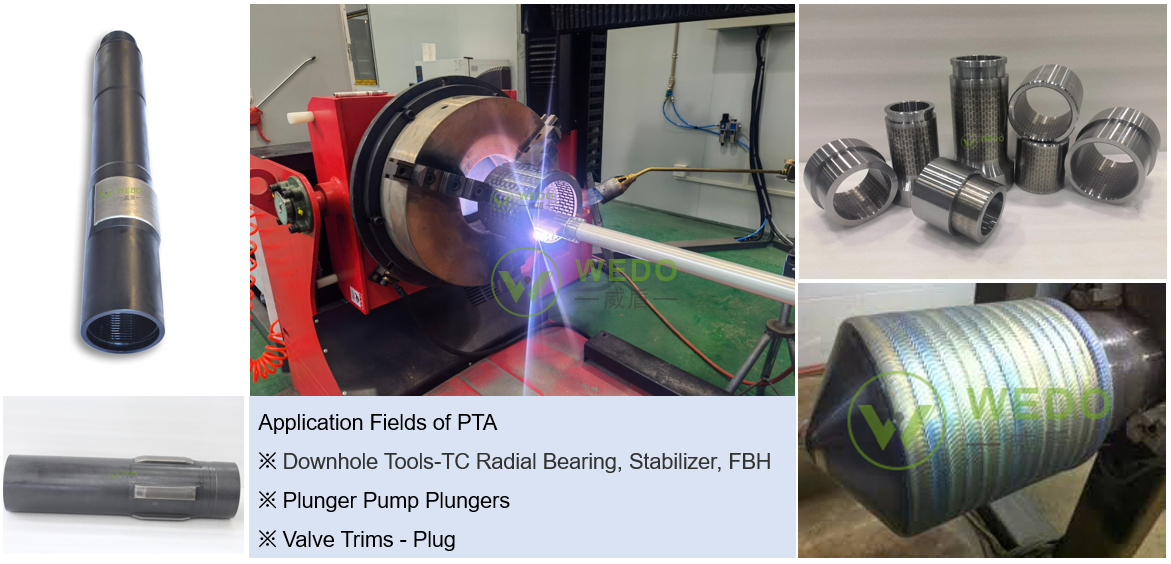

Typical Parts & Applications please refer below image

Advantages of PTAW process

1>.Low dilution rate.

2>.High Bonding Strength, which is metallurgical bonding between base metal and matrix powder.

3>.Small HAZ(Heat affected zone).

4>.Wide usage of powder materials.

Contact: Allen Yu

Phone: 0086-15116055332

Tel: 0086-731-28202108

Email: Sales@wedo-material.com

Add: Tianyi Hi‐Tech Park, Zhuzhou City,Hunan Province, China

We chat