PDC bearings are very wear-resistant, compared with traditional tungsten carbide bearings or other cemented carbide bearings, the service life is 4-10 times longer depending on different operating conditions. PDC bearings utilizes brazing process to form radial or thrust bearings, which enables them to be used in mud motors and turbines, thereby extending tool life and improving tool stability and reliability.

PDC Thrust bearings ensure that parallelism, surface finish and quality meet your requirements.

Features of PDC Thrust Bearings | ||

Parallelism | Flatness | Tension Strength |

Max. 0.02mm | Max. 0.01mm | 200MPa Min. |

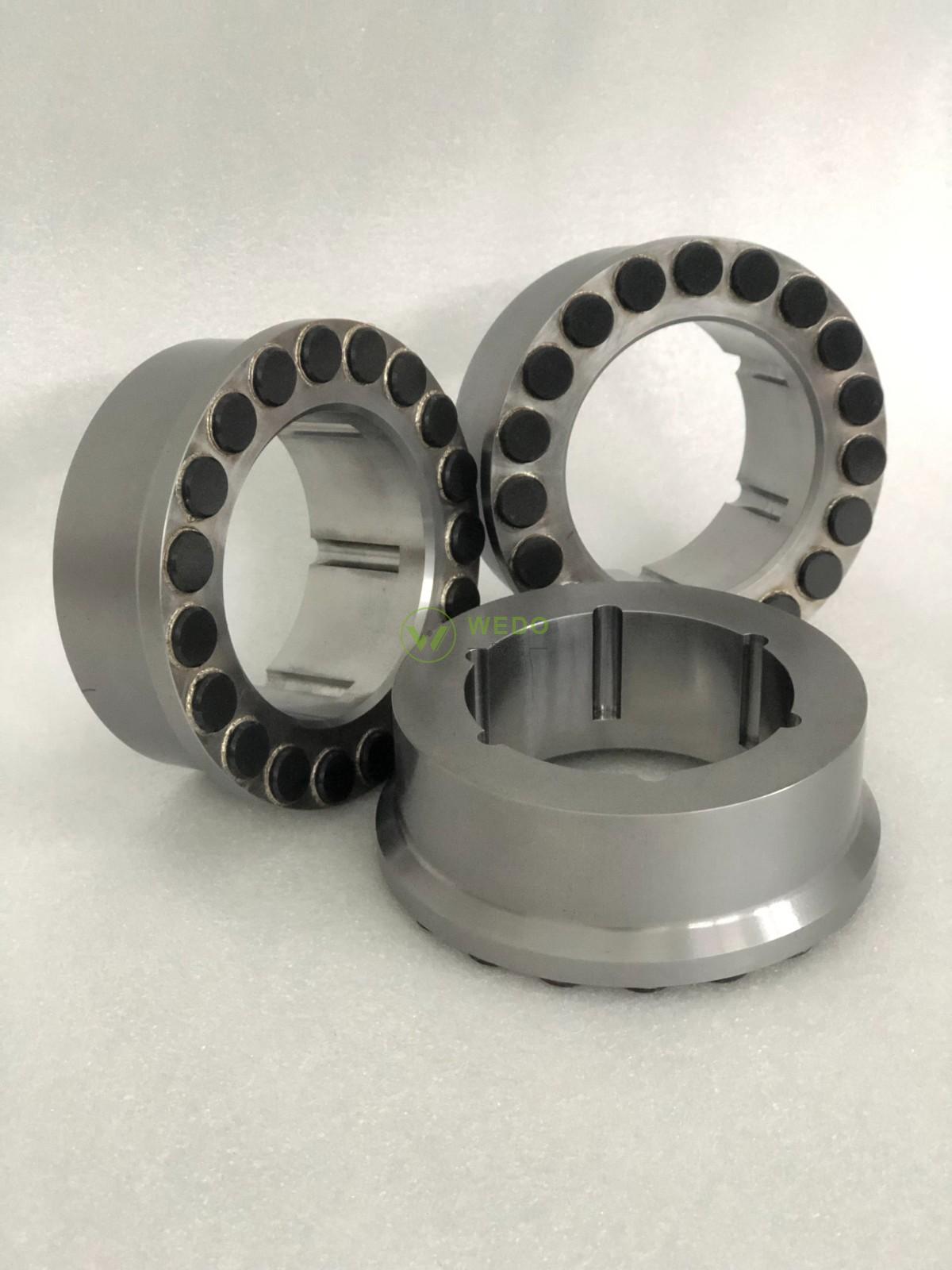

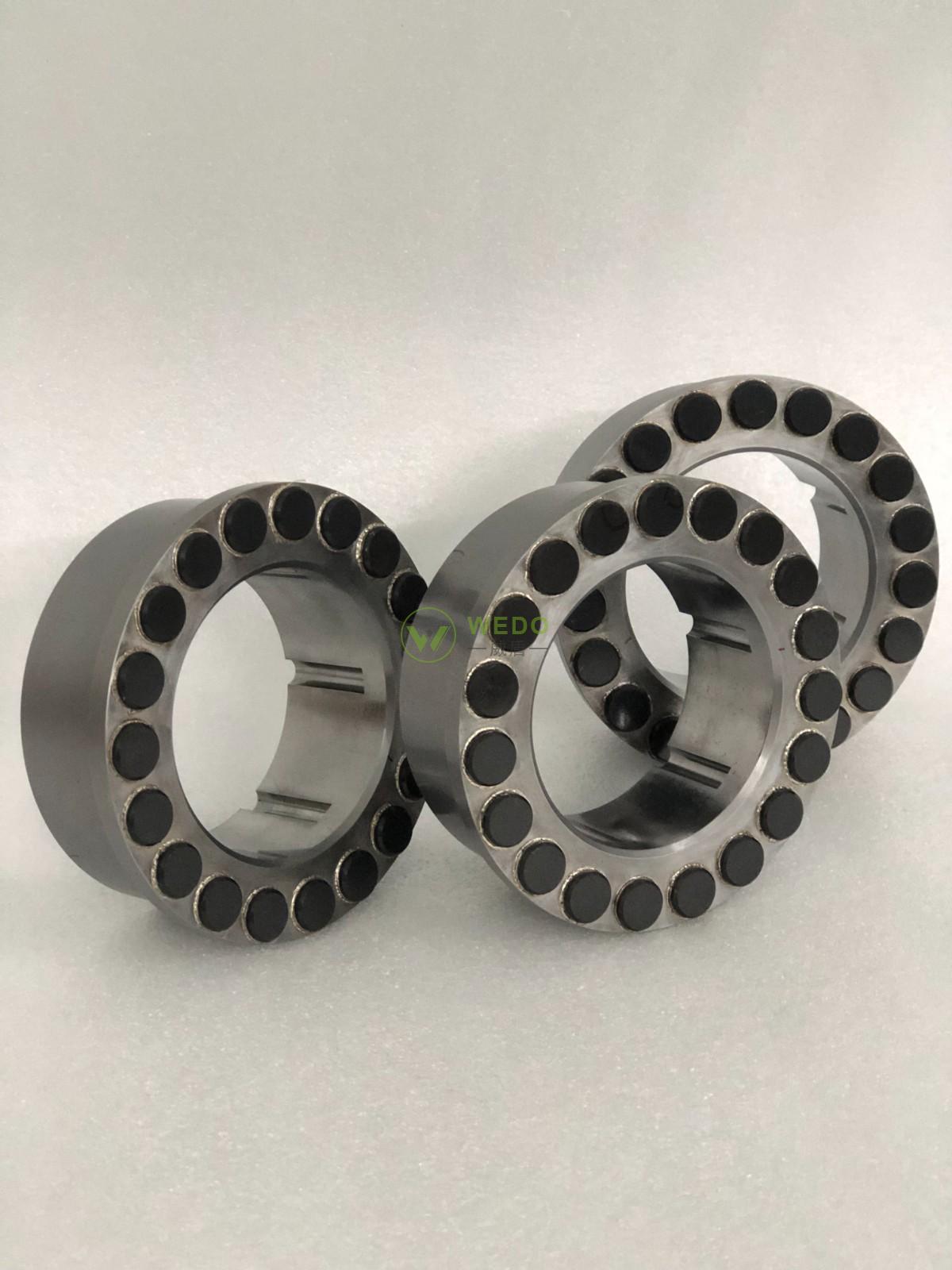

PDC Radial bearings to ensure concentricity, surface finish and quality meet your requirements.

Features of PDC Radial Bearings | ||

Coaxiality | Concentric | Roundness |

Max. 0.05mm | Max. 0.05mm | Max. 0.05mm |

Advantages of PDC bearings

※ Ultra-high wear resistance, corrosion resistance and mechanical fatigue resistance.

※ Extremely resistant to chipping, cracking and spalling, which are inherent problems in cladding coatings or surfacing processes.

※ Good thermal conductivity

Application Fields.

※ Downhole turbine drill tools, Mud motors.

※ Rotary Steerable Systems.

※ Sevage Treatment

Specifications of PDC bearings

Our PDC bearings and wear parts can be customized according to customer's precise drawings or samples.

Contact: Allen Yu

Phone: 0086-15116055332

Tel: 0086-731-28202108

Email: Sales@wedo-material.com

Add: Tianyi Hi‐Tech Park, Zhuzhou City,Hunan Province, China

We chat